Quality Standard

Quality Standards of Granite, Marble Slab & Tile

| S.R | Class of Granite | Categories | Polishing Process | Specification | Manufacturing Cost |

Premium Quality Granite | A Class Granite | Grinding Grit – 16 to 80 Closing of Pores Grit – 120 to 220 Honing Grit – 280 to 400 Pre Polishing Grit – 600 to 1500 Polishing Grit – 2000 to 3000 Mirror Finish Buffing and Rubbing Polishing Degree Result= Gloss Unit – 85 to 98gu High-quality nano polishing gives a lustrous appearance. | Fresh and Fine Blocks are taken from the quarry with Zero tolerance in Irregularities, Fractures, Color Variations, Bonding of Particles, and quality of the stone. Optional or If required Granite is Treated with Imported high-quality epoxy and equipment’s used are of very High Precision. Inspection Of every slab and tile for Polish, Flatness, and Straightness of Edge with all instruments to maintain quality standards. The rejection rate of slab and tile is very high due to strict Inspection. Quality Assurance and warranty have been provided on each slab and tile Precautionary measure – Extra slabs will have provided so that, they could be used if any mishap happens. | Very High | |

B Class Granite | Grinding Grit – 16 to 80 Honing Grit – 280 to 400 Pre Polishing Grit – 600 to 1500 Polishing Grit – 2000 to 3000 Polishing Degree Result= Gloss Unit – 75 to 85 gu | Fresh and Fine Blocks are taken from the quarry with Zero tolerance in Irregularities, Fractures, Color Variations, Bonding of Particles, and quality of the stone. Optional or If required Granite is Treated With Imported high-quality epoxy. Inspection Of every slab and tile with all instruments to maintain quality standards Precautionary measure – Extra slabs will have provided so that, they could be used if any mishap happens. | Moderate | ||

C Class Granite | Grinding Grit – 16 to 80 Honing Grit – 280 to 400 Pre Polishing Grit – 600 to 1500 Polishing Grit – 2000 – 2500 Polishing Degree Result = Gloss Unit – 70 to 80 gu | Fresh and Fine Blocks are taken from the quarry with Zero tolerance in Irregularities, Fractures, Color Variations, Bonding of Particles, and quality of the stone. Optional or If required Granite is Treated With Imported high-quality epoxy. Inspection Of every slab and tile with all instruments to maintain quality standards Precautionary measure – Extra slabs will have provided so that, they could be used if any mishap happens. | Economical |

HOW TO USE ABRASIVE

Selection & Use of Abrasives For Granite & Marble

Natural stones like granite and marble are capable of taking a high polish and are therefore used as decorative stones for cladding purposes in the construction industry, as well as for monumental and memorial work.

The basic difference between marble and granite is that marble is formed by the metamorphosis of lime and is, therefore, a much softer stone as compared to granite which exists in nature as igneous rock and is quite hard.

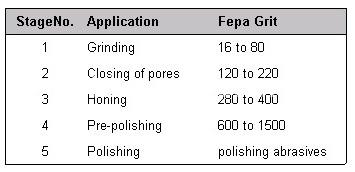

The basic principle of polishing any natural stone is to hone the surface of the stone by progressively using a finer mesh of abrasives until the natural luster of the stone is obtained.

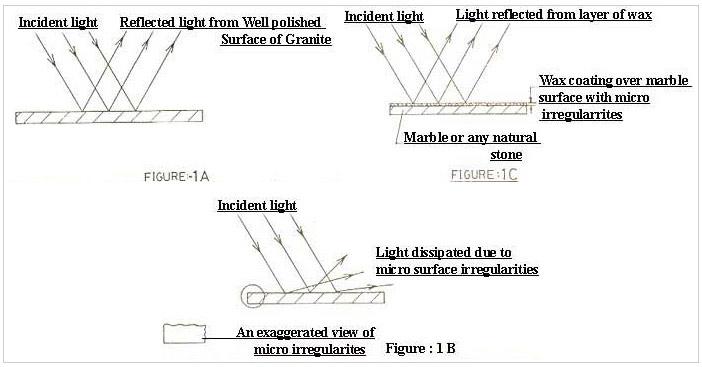

A Polished Piece Of Natural Stone Is Capable Of Reflecting A Major Portion Of The Light Falling On It. (See Fig. 1A). A Surface Which Is Not Honed Properly And Therefore Has Irregularities Is Not Able To Reflect A Substantial Portion Of The Incident Light. Instead, It Dissipates The Light (See Fig 1B). As A Result, The Viewer Finds That The Surface Lacks A Certain Lustre.

1. Selection Of The Sequence Of Abrasives (For Polishing Granite)

It is very important that the initial grinding be carried out thoroughly with the rough grits in order to make the surface of the granite absolutely flat. It is important to remember that the quality of the polish depends entirely on the quality of the flatness achieved by the initial grinding and honing process. Many times, operators ignore the first two stages and concentrate on the application of the polishing abrasives in an attempt to get a high gloss, but this will not help unless the grinding and closing of the pores of the granite are carried out successfully.

2. Selection Of The Bond Of Abrasives

The selection of the bond of the abrasives depends on the sawn surface of the granite, the quality of granite, and the production rate required. In general, soft bond abrasives will give a faster rate of production and are normally used for polishing monuments & tiles. Hard bond abrasives last longer and are extensively used in the polishing of rough gang sawn slabs where the wear and tear of the abrasive are excessive.

3. Required Polishing Pressure

The grinding pressure determines the rate of material removal. However, excessive grinding pressure may cause burn marks, scratches, breakage of granite slabs/abrasives. Normally hard and porous granites like Red Granite require higher pressure as compared to softer granites like black granite. The pressure also depends on factors like Conveyor Speed, Bridge Speed, type of machine, type of abrasive, etc.

4. Adequate Water Supply

Adequate flow of water is a must for good grinding, honing and polishing. A copious supply of water will ensure good surface preparation and will inhibit burn marks and scratches. The finer mesh abrasive should preferably have a supply of fresh water to ensure scratch-free polish.

The belt speed in the Line Polishing Machine and the number of passes in the Bridge Polisher will determine the quality of polish as well as the rate of production. In-Line Polishing machines the belt speed should be restricted to a level where a clear and acceptable polish is achieved. Higher speeds than required, may cause uneven polish, bum marks, scratches, dullness etc. Likewise, the Bridge polisher should also have an adequate number of passes to ensure complete grinding and polishing

Product Specification | All South Indian and North Indian Granite |

Name of the Product | Granite Tile, Slab for Countertop and Flooring Project. |

Block Size | 60*180*60 cm & up, 120*240*120 cm & up, 150*270*150 cm & up and can customize according to customer preference. |

Gangsaw Slab | 280*160 cm, 280*220 cm, 340*160 cm, 340*220 cm |

Random Slab | 60*180 cm and up, 120*240 cm & up and customizable. |

Cut to size | 30*30 cm, 30*60 cm, 40*40 cm, 40*60 cm, 60*60 cm, 60*90 cm, 70*120 cm, 70*130 cm, 70*140 cm (Size can be Customize). |

Thickness | 10mm, 12mm, 15mm, 16mm, 18mm, 20mm, 30mm, 40mm. |

Tiles | 305*305*10 mm, 305*610*10 mm, 457*457*12mm. customizable |

Finishes | Polished, Honed, Brushed, Leather, Textured, Bush hammered, Rough, Flamed. |

Quality Management | 1, Polishing at 85 – 95 GU ( Premium polish ) Polishing at 75 – 85 GU ( Standard Polish ) Polishing at 65 – 75 GU ( Sub Standard Polish ) |

Packing | Sea freight with strong wooden crates. With fumigation worthy to the |

Stuffing Capacity for Export of Granite in 20’ Container | |||

Product | Thickness | Quantity | Weight |

Slab | 20mm 30mm | 400 – 425 Sqm 270 – 300 Sqm

| 22000 Kg 22000 Kg |

Cut to Size | 18mm 20mm | 420 – 440 Sqm 400 – 425 Sqm | 22000 Kg 22000 Kg |

Tiles | 30mm 10mm | 270 – 300 Sqm 800 – 820 Sqm | 22000 Kg 22000 Kg |

Container details

Container Type | Out Side Dimension | Inside Dimension | Top opening | Cubic Capacity |

20 Feet | 6.045×2.438×2.438 | 5.90×2.35×2.387 | – | 31 cbm1,079 cu ft. |

20 Feet High Cube | 6.045×2.438×2.591 | 5.918×2.337×2.413 | – | 31 cbm1,079 cu ft. |

20 Feet Open Top | 6.045×2.438×2.438 | 5.918×2.337×2.286 | L: 5.41m, W: 2.21m | 32 cbm1,116 cu ft |

Granite capacity per container

Size | Q. SFT. | Details (20’ container) |

1x1x10mm | 7200 | Packing in Thermocol & Wooden Crates,20 Pallets in Container, 1 Pallet 36 Box, 1 box 10 Pcs. |

1’X1’X10MM | 8000 | Without Thermocol Packing, In Corrugated Box Packing |

2’6”x8’x20mm | 5400 | Wooden Boxes and Crates |

4’x12’x20mm | 3500 | Wooden Boxes and Crates |

5’X9’X20MM | 3200 | 70 SLABS |

5’X9’X30MM | 2400 | 49 SLABS |

30”x240x11MM | 5500 | 275 SLABS, Each Slabs Wrap in Bubble Rap & Within two slabs full Thermocol sheet, in a special wooden crate. |

Weight

Size | Weight |

1’X1’X10MM | 2.5 KG |

1’X1’X20MM | 5.00 KG |

1’X1’X30MM | 7.50 KG |

Quality Technicals for Stone Article

Name |

Garden Fountain, Flower Pots and Urns, Balustrades, Tombstone & Monument |

Size | All Articles are customizable. We design all our articles on customers’ preference for size. |

Material | Granite, marble, and sandstone. |

Technics | Polished, Honed, and Antique. |

Advantage | An experienced and skilled artisan will produce elegant products and we will customize them as per the customer’s needs. |

After-sale service | Online Technical support |

Project solution feature | CAD Drawing given with the product. |

Arrival time | 40-60 days (15 – 20 days to produce, 25-35 days to transport) may vary according to order. |

Application | Last ritual, funeral decoration. |

Packaging | The Articles packing ways: 1. Solid wood crates packed by 2*8 cm wooden slabs which need fumigation 2. Inside the crates with enough wood chunks or foams to support the inner products, avoid goods shaking. 3. Inside the crates with plastic film to prevent water come in. |

Quality Standards | 1. Strict Quality control and supervision system Guarantee good quality. 2. First inspection select a grade A raw material 3. The Third inspection is to check pieces by pieces color difference control. 4. Well packed to prevent damage during long-distance transport. |

| |

Color – Yellow, white, black, green, beige, and from our available inventory.

| |

Dimensions – all are customizable as per your need and we leave on our customer’s requirements.

| |

| |